Minimize CO₂ emissions in board and paper production

Innovative technology, the right services for reliable production, raw material and energy efficiency, fossil-free energy sources and circularity – they all help us fight against climate change and play a key role in the transition to a carbon neutral economy. Valmet’s target is to enable carbon neutral board and paper production by 2030 at the latest.

Towards even more sustainable board and paper making

We offer unique solutions for reducing CO2 emissions and other environmental impacts in board and paper production through a combination of process technologies, services and automation solutions. With our long experience and innovative solutions, we can help you significantly reduce your CO2 emissions – as well as your operational costs.

A complete offering for board and paper makers

Our key objective is to enhance the competitiveness of our customers’ processes by improving the productivity and efficiency of their production lines and promoting sustainable paper production through the best available technology and innovative technological solutions.

Our comprehensive services and automation offering help to maximize the environmental efficiency of the technologies and ensure operational safety and reliability over the entire lifetime of the plant.

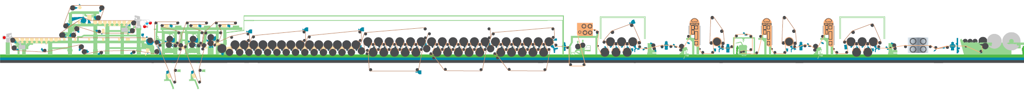

|

Electricity |

CO2 emissions |

|

-16 % |

-14 % |

Total saving potential for a paper machine. Calculations are based on an optimized coated board machine with the best available technology excluding stock preparation.

Want to reduce your environmental footprint?

Our experts can support you to find the most suitable solutions for your sustainability needs.

Contact our expertsImprove your sustainability with Valmet's services

Valmet’s service expertise supports you in improving the efficiency of operations and stabilizing the manufacturing process throughout the life cycle, ensuring a minimized environmental footprint. By combining our experts’ long-term experience with yours, our cooperation enables continuous process optimization. This means improved energy efficiency, decreased raw material and water use, and thus lower operating costs for the desired output. In addition, our onsite and remote services support you in decreasing CO₂ emissions, enhancing circularity, and ensuring the proper maintenance of your production equipment. It’s about the right services and solutions at the right time.

Explore solutions to minimize CO2 emissions

Nippon Dynawave: sustainable board with less CO₂ emissions and fibers

Nippon Dynawave wanted to go towards a more sustainable board production. They succeeded in reducing greenhouse gas emissions and using less fibers for the same amount of board with the Valmet-supplied metal belt calender. Watch the video to find out more!

Our sustainable solutions for board and papermakers

Explore our latest board and paper press releases

- Sep 26, 2024Metsä Board Simpele improves working conditions and safety with Valmet Fold-up Wall

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry