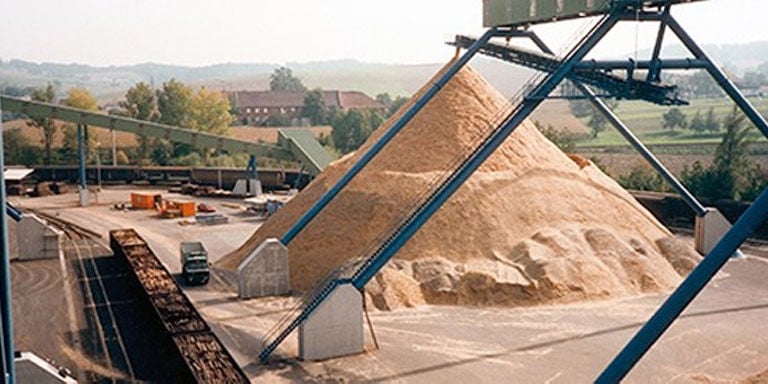

Chip storing

Cutting-edge technology for wood-chip storage and reclaiming

Valmet’s chip handling and storage concept offers several storage and reclaiming solutions to suit any customer need.

Excellent chip blending

Gentle and automatic reclaiming

First-in first-out operating principle

Low operation and maintenance cost

High stacking and reclaiming capacity

All equipment visible and easy to access

Enables easy and flexible mill layout

Valmet Circular Chip Storage provides the latest cutting-edge technology for wood-chip storage and reclaiming. This chip storage system operates on the first-in first-out principle, meaning the chip pile is built up at the front and reclaimed from the back. The chips are reclaimed gently from the whole cross section of the pile, which ensures excellent blending and homogenization of the chips while minimizing chip damage. Valmet Circular Chip Storage includes several unique features and allows low operation and maintenance costs, making it a beneficial total investment.

Silos with rotary or traversing screw reclaimer

The Valmet Screw Reclaimer, traversing type, is designed for automatic and reliable reclaiming of chips, bark or saw dust from an open pile or storage silo. No bulldozers or front loaders are needed, which means minimal chip damage.

Rotary and Traversing screw reclaimer

Chip storage is necessary to ensure the optimal supply of chips to the process. The Rotary screw reclaimer and the Traversing screw reclaimer are designed for reliable reclaiming of chips, bark or sawdust from a storage silo or open pile. The large reclaiming opening minimizes the need for front loaders in open piles. 100 % automated reclaiming is achieved from silo storage.

Long Lifetime and Easy Maintenance

A long lifetime is ensured by the heavy-duty reclaimer design combined with low rotation speed. The drive units and other service points are easily accessed which makes maintenance easy.

Rotary screw reclaimer operation

This machinery features high reliability thanks to the extremely strong and simple construction. The cantilever screw reclaimer rotates slowly under the pile, feeding material through a hopper onto the conveyor beneath. The reclaim rate can be adjusted by a frequency converter (optional feature).

Traversing screw reclaimer operation

The reliability is high thanks to the extremely strong and simple construction. The cantilever screw reclaimer is supported on two tracks, one installed on the service tunnel ceiling and the other on the floor. Material is reclaimed onto the conveyor below by the rotating screw. At the same time the reclaimer moves slowly along its track. The reclaim rate can be adjusted by a frequency converter (optional feature). One or more screw reclaimers can be installed on the same track.

RecAll and RotaRecAll reclaimer

Chip storage is necessary to ensure the optimal supply of chips to the process. The RecAll and RotaRecAll reclaimers are designed for automatic and reliable reclaiming of chips, bark or sawdust from a large-volume silo. The automatic reclaiming prevents chip pile deterioration. Since no bulldozers or front loaders are needed, chip damage is minimal.

RecAll reclaimer

The first in-first out principle reclaims chips from the bottom of the chip pile, eliminating the deterioration of the chips during storage. Reclaiming through the whole width of the pile guarantees excellent blending and homogenization of the chips. An extremely wide reclaim opening enables high-volume storage with automatic reclaiming.

Operation

The RecAll screw reclaimer is supported on a track at both ends of the screw. Material is reclaimed by the rotating screw onto a conveyor. At the same time, the reclaimer moves slowly along its track. The reclaim rate can be adjusted by a frequency converter (optional feature). One or more RecAll reclaimers can be installed on the same track.

RotaRecAll reclaimer

RotaRecAll reclaims through the whole cross-section of the chip silo. This, combined with the first-in first-out principle, guarantees excellent homogenization of the chips for further processing.

Clean Chips - Clean Environment

With the RotaRecAll reclaimer, it is possible to build large silos for 15,000 – 26,000 m3 chips. Silo storage eliminates wind screening and keeps chips clean. It also prevents the release of dust and noise into the environment.

Operation

The RotaRecAll screw reclaimer is supported at both the center and periphery of the silo. The screw slews slowly under the pile, feeding material through a hopper onto the conveyor beneath. The reclaim rate can be adjusted by a frequency converter (optional feature).

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and ensure smooth, disruption-free operation, supporting you all the way.

Contact us